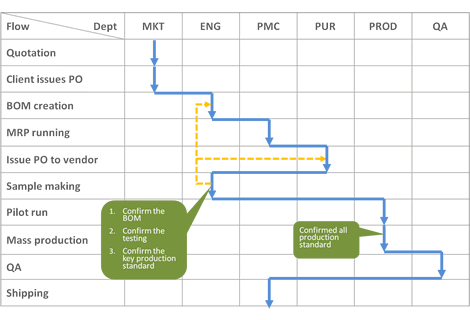

在龙健,NPI(新产品导入)是一个团队共同参与营销,工程设计,PMC(生产及物料控制),采购,生产和质量保证。以下流程图显示他们工作在不同的阶段。

整个NPI新产品导入流程是由有项目管理背景的工程部经理进行管理和推进的。

NPI流程图

It starts with the quotation stage which is initiated by marketing. Engineering study the technical package, estimate the production process time and preliminarily work out a list of tool and fixtures needed. Purchasing quote the pricings of the components listed in BOM (bill of material). Our quotations are all true open book quotations. That means, we can provide all the cost break down and we don’t put any hidden mark-up on the materials.

The project is confirmed and set to kick off. Engineering load the BOM into the MRP system. PMC generate the material shortage list and signal purchasing to start materials procurement. Prior to all these, a master schedule has been made by the NPI manager. So, material planner and purchasing co-work the material schedule with the suppliers based on the schedule.

Meanwhile, engineering and QA need to prepare quite many documentations: a draft of work instruction, a draft of process flow, a draft of quality plan; and make the tools and fixtures needed for productions and inspections.

When everything is ready, engineering make a few pieces of samples. This is to make sure: the BOM is correct; the testing procedure is correct; and the production standard is correct.

Sample is OK. Pilot run starts. It is an opportunity for engineering to transfer their knowledge gained in sample making to production. Everything (BOM, operators, production facilities, processes, inspection standard) in pilot run is supposedly same as that in following mass productions.

Mass production starts after pilot run with very limited, if not none, of engineering support. It is because production has already learned the knowledge and experience from engineering during pilot run.

Before the shipment, QA inspect the products as planned.

扫描二维码,关注我们